Why Grain and Seed Processing Matters for Industrial Operations

Grain and seed processing is the series of industrial operations that transform raw harvested crops into safe, stable, marketable products. These operations include cleaning, drying, grading, sorting, and treating the material to remove impurities, reduce moisture, and standardize quality. These actions prepare the grains and seeds for storage, sale, or further manufacturing.

The primary goals of industrial grain and seed processing are:

- Quality improvement – Remove foreign material, broken kernels, and off-grade product

- Safety assurance – Eliminate contaminants and control the moisture level to prevent mold and mycotoxins

- Storability improvement – Reduce moisture content to safe levels (typically 10-15%) to prevent spoilage

- Value creation – Grade and sort to meet market specifications and command premium prices

- Loss minimization – Recover maximum usable product from harvested material

The global grain processing market is projected to reach $315.8 billion by 2030, yet post-harvest losses for cereals can be as high as 40%. This makes efficient processing equipment and methods critical for any operation handling bulk grains or seeds.

Whether processing wheat for flour, seed corn for planting, or soybeans for oil, the right equipment directly impacts yield, quality, and profit, . Each grain type requires specific handling to preserve quality and maximize recovery. Modern industrial facilities use specialized equipment including aspirators, gravity separators, screen cleaners, dryers, and automated control systems to achieve consistent results at scale.

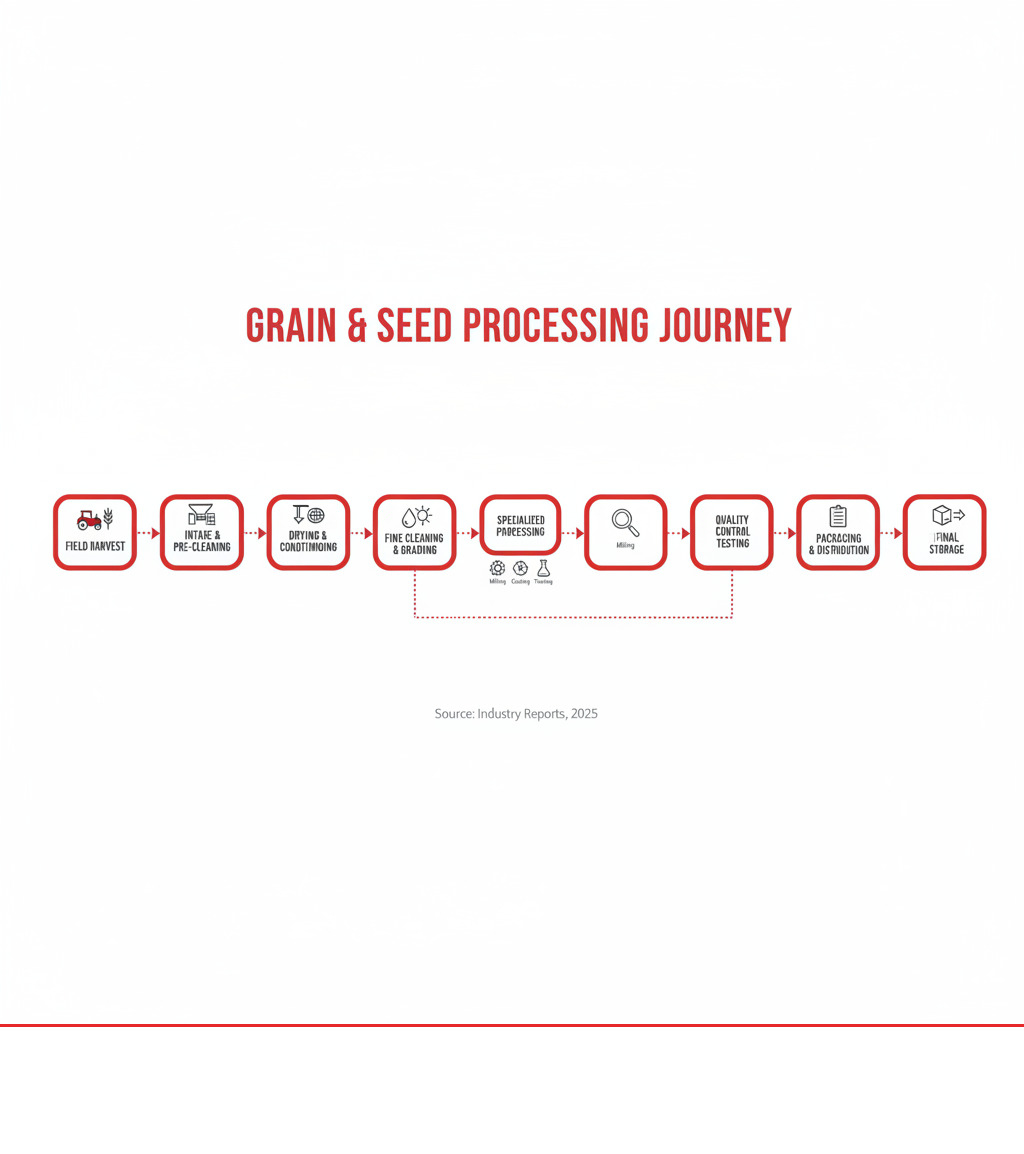

The Core Stages of Industrial Grain and Seed Processing

Grain and seed processing transforms raw, debris-filled grain into a clean, stable, market-ready product. The journey typically flows through intake, pre-cleaning, drying, fine cleaning, grading, specialized processing, and storage. Skipping steps or using inferior equipment compromises yield and quality, while proper execution maximizes recovery and meets strict standards.

For industrial-volume operations, the right equipment makes all the difference. Our insights on The Critical Role of Industrial Grain Screening Equipment in the Agriculture Industry explore why proper screening is foundational to successful processing.

Stage 1: Intake and Pre-Cleaning

Raw grain typically arrives with rocks, stalks, leaves, and dirt that can damage downstream equipment. Pre-cleaning, or scalping, is the first line of defense. Drum scalpers remove oversized debris at high capacities, while aspirators use airflow to lift lighter material, such as chaff and dust, based on aerodynamic profile and density.

This initial step is also crucial for dust control. Combustible grain dust is a major safety hazard, making proper ventilation and dust collection systems essential. Efficiently moving bulk materials through your facility is fundamental, as covered in our article on Bulk Material Handling: Exploring the Mechanics and Optimal Equipment Solutions.

Stage 2: Drying and Conditioning

Harvested grain contains excess moisture (18-20% or more), creating a breeding ground for mold, bacteria, and insects. Moisture content management is a must with most products aiming for a safe storage level of 10-15%, depending on the commodity. This single step prevents spoilage and protects product value.

Industrial dryers must reduce moisture uniformly without damaging the grain, as overheating can crack kernels or destroy germination capacity in seed crops. Our Thermal Processing Systems are engineered for this delicate balance, protecting both storability and germination potential.

Stage 3: Fine Cleaning, Grading, and Sorting

With moisture controlled, the focus shifts to purity. Fine cleaning removes smaller impurities, such as weed seeds, foreign grains, and broken kernels, that can lower product quality.

Precision equipment is key. Screen cleaners are separated by size, gravity separators (or gravity tables) are separated by weight, and indented cylinders are graded by length. This meticulous grading by size, density, and quality ensures a premium product. For the highest purity standards, optical sorters can detect and remove discolored or defective kernels based on visual characteristics. The CIGR Handbook of Agricultural Engineering, Volume IV Agro Processing Engineering, Chapter 1 Grains and Grain Quality, Part 1.1 Grain Quality offers more insight into these quality factors.

Stage 4: Value-Add Processing and Handling

Value-add processing takes clean grain a step further. This includes milling wheat into flour, hulling rice or oats, or flaking grains for cereals and feed. For seed operations, coating adds protective chemicals or nutrients. Uniform application is critical, and our Mixing Systems ensure even distribution.

When reducing particle size, hammer mills or roller mills are used, as explored in our Size Reduction Equipment white paper. Throughout these steps, gentle handling is vital. Our Conveying Systems move materials efficiently while preserving product integrity.

Essential Equipment for Modern Grain and Seed Processing

Exceptional grain and seed processing relies on durable, high-performance equipment. At S. Howes, we build industrial machinery designed to last for decades, ensuring the quality and efficiency your operation demands. A modern facility needs a full range of specialized machinery for separation, sizing, and conditioning. Our comprehensive Screening equipment is foundational to many successful operations.

Separation and Sizing Equipment

Separation and sizing equipment acts as the quality gatekeeper for your processing line, purifying and standardizing your products.

Screeners are the workhorses, using vibratory motion and perforated screens to separate materials by size. Gravity tables perform the intricate work of separating products based on small differences in density. Using a vibrating deck and controlled airflow, they stratify materials, separating heavier, viable kernels from lighter, undesirable material. When separating by shape or length, indented cylinders use rotating, pocketed cylinders to lift out shorter or longer particles. Finally, aspirators use an upward air current to lift away lighter materials like dust and chaff. Together, these machines provide a comprehensive system for separating by size, shape, density, and aerodynamics.

Size Reduction and Conditioning Equipment

Once separated, grain often requires a change in physical form for its intended use. Hammer mills are the go-to for breaking materials into smaller particles for flour or animal feed. For more precise control, roller mills offer a gentler approach, crushing or flaking grains with minimal heat. Flakers create products for breakfast cereals or specialized feeds. For crops like rice or oats, de-huskers (or hullers) remove the outer shell. Each machine prepares the grain for its final application.

Treatment and Improvement Equipment

Value can be added through final treatments that lift materials to premium status. Seed coaters apply uniform layers of protective chemicals, nutrients, or colorants, ensuring every seed receives consistent coverage. This process improves germination and adds significant value. For applications that require precise temperature control during blending, thermal mixers are essential. These machines, sometimes referred to as a heating mixer, apply treatments while heating the ingredients via an external jacket, which is crucial for specialized feed formulations. Finally, polishers improve the appearance of grains like rice and legumes by removing the outermost layer, creating a natural shine. This equipment transforms basic commodities into premium, value-added products.

Ensuring Quality, Safety, and Efficiency

Modern grain and seed processing requires more than just moving material. It demands systems that deliver consistent quality, ensure safety, and maximize efficiency. The right combination of automation, safety protocols, and smart equipment choices can transform an operation from functional to exceptional.

The Role of Automation in Grain and Seed Processing

Automation is revolutionizing industrial processing. PLC controls act as the brain, orchestrating the entire line from intake to packaging. Data integration allows for complete lot tracking, which is essential for quality control and regulatory compliance.

The economic benefits are clear: reduced labor costs, increased throughput, and consistent quality by removing human variability. Automation also improves safety by reducing worker exposure to dusty environments and repetitive tasks, allowing them to focus on skilled monitoring and maintenance.

Upholding Food Safety and Quality Standards

Food safety is about protecting consumers and your brand. Dust control is a major focus, as combustible grain dust is both a safety hazard and a source of product loss. Our systems incorporate effective dust collection at every stage.

Metal detection and foreign object screening protect consumers and downstream equipment. We also design for cross-contamination prevention using easy-to-clean equipment, which is critical for allergen control. Complete traceability from seed to shelf enables rapid response to quality issues. We use food-grade materials, such as 304 stainless steel, to meet stringent requirements for facilities that process human-consumption products, as detailed in our work on Food and Pet Food Processing.

The Economic Case for Advanced Processing Systems

Investing in advanced processing equipment is a sound business decision. Efficient systems directly reduce post-harvest losses, which can be as high as 40% in some regions. Every percentage point recovered is direct profit. Maximizing yield means getting every usable particle into the right grade, with precise grading separating premium products that command top prices.

The return on investment (ROI) can be rapid; we’ve seen systems pay for themselves in months through improved efficiency and reduced loss. By creating value-added products—like specialty flours or coated seeds—you can open new markets and improve margins. Our durable equipment, some running for over 75 years, ensures your investment continues to pay dividends for decades.

The Future of the Grain and Seed Processing Industry

The grain and seed processing industry faces new challenges and opportunities driven by rising global demand and evolving consumer expectations. With decades of experience—some of our machines have been running for 75 years—S. Howes is committed to helping clients steer the future of processing.

Key Challenges and Emerging Trends

Processors today face significant pressures. Labor shortages make automation a necessity, not a luxury. Rising energy costs demand more efficient equipment. The growing demand for traceability requires sophisticated data integration to track lots from field to shelf.

On the technology front, AI-powered sorting and advanced sensor technology are improving quality control with remarkable precision. Data analytics provides powerful insights, enabling predictive maintenance and process optimization to maximize yield and reduce waste. These trends are shaping the next generation of processing facilities.

Integrating Sustainability into Modern Practices

Sustainability is now a business imperative, and it often aligns with economic efficiency. Energy-efficient equipment is key, lowering utility costs while maintaining performance. Waste reduction is another focus; optimizing separation processes minimizes loss and maximizes sellable product.

Forward-thinking processors are also finding value in by-products, turning former waste into animal feed or biomass for energy. Our article on Biomass 101: What You Need to Know explores this growing field. Water conservation is also an important consideration in many processing applications.

Adapting Processes for Different Grains

There is no one-size-fits-all approach to processing; different crops have unique needs. A system optimized for wheat will differ from one for soybeans or lentils.

Cereals like rice require specialized hulling, while seed corn needs gentle handling to protect germination. Oilseeds such as soybeans must be handled carefully to prevent premature oil release during extraction. Legumes are often delicate and require systems that minimize breakage to maintain market value.

| Grain Type | Special Considerations for Processing |

|---|---|

| Cereals (wheat, corn, rice, oats) | Wheat requires precise milling control for various flour grades; corn for seed needs gentle handling to maintain germination; rice demands specialized hulling equipment; oats benefit from dehulling for human consumption |

| Oilseeds (soybeans, sunflower, flax, canola) | Require gentle handling to avoid premature oil release; cleaning must remove field debris without damaging seed coat; conditioning is critical before oil extraction; size uniformity improves extraction efficiency |

| Legumes (beans, peas, lentils, chickpeas) | Minimizing breakage is essential for market value; gentle conveying and separation required; color sorting removes discolored seeds; careful moisture management prevents splitting during drying |

At S. Howes, we understand these distinctions. Our custom American-made equipment is engineered to your commodity’s specific requirements, and our product testing lab ensures the solution meets your exact needs.

Frequently Asked Questions about Grain and Seed Processing

What is the primary goal of grain and seed processing?

The primary goals of grain and seed processing are to improve product quality by removing impurities, ensure safety by controlling moisture and contaminants, improve storability for long-term stability, and increase market value by grading products to meet buyer specifications. Our equipment is designed to maximize recovery of usable product while upholding the highest quality standards.

How does processing reduce post-harvest losses?

Post-harvest losses, which can reach 40% in some regions, are a major threat to profitability. Grain and seed processing directly mitigates these losses. Drying to a safe moisture content (typically 10-15%) prevents mold, bacteria, and insect infestation. Cleaning removes pests and foreign material that can contaminate an entire lot. Properly processed and stored grain is a stable asset, allowing you to steer market fluctuations. Investing in efficient industrial equipment protects your product and your bottom line.

What’s the difference between cleaning and grading?

This is an important distinction in grain and seed processing. Think of it this way: cleaning is about purity, while grading is about uniformity.

Cleaning is the process of removing everything that shouldn’t be there—dirt, stones, weed seeds, chaff, and other foreign material. It’s about achieving a pure product.

Grading, on the other hand, sorts the clean product into categories based on quality criteria such as size, density, or shape. It ensures uniformity within each grade.

In short, cleaning removes the bad stuff, and grading organizes the good stuff. Both steps are essential for maximizing the value of your harvest.

Conclusion

From raw crop to finished good, grain and seed processing is about changing agricultural products into safe, stable, and valuable commodities. This journey is guided by three principles: quality, safety, and value creation. Achieving these requires thoughtful planning and durable, reliable equipment. The right machinery doesn’t just work; it performs for decades—some of our equipment has been running for over 75 years.

At S. Howes, we design and manufacture custom American-made equipment in Silver Creek, New York. We reject one-size-fits-all solutions. Using our product-testing lab, we develop custom systems to address your unique challenges, whether you’re processing wheat, seed corn, or soybeans.

By minimizing losses, maximizing yield, and producing high-quality products, an advanced processing system is a strategic investment with a substantial return. We’ve seen operations achieve payback in as little as seven months. As the industry evolves, the right partner and equipment turn challenges into opportunities.

Ready to lift your grain and seed processing? Explore our advanced grain cleaner solutions and find the power of durable, quality-driven engineering.