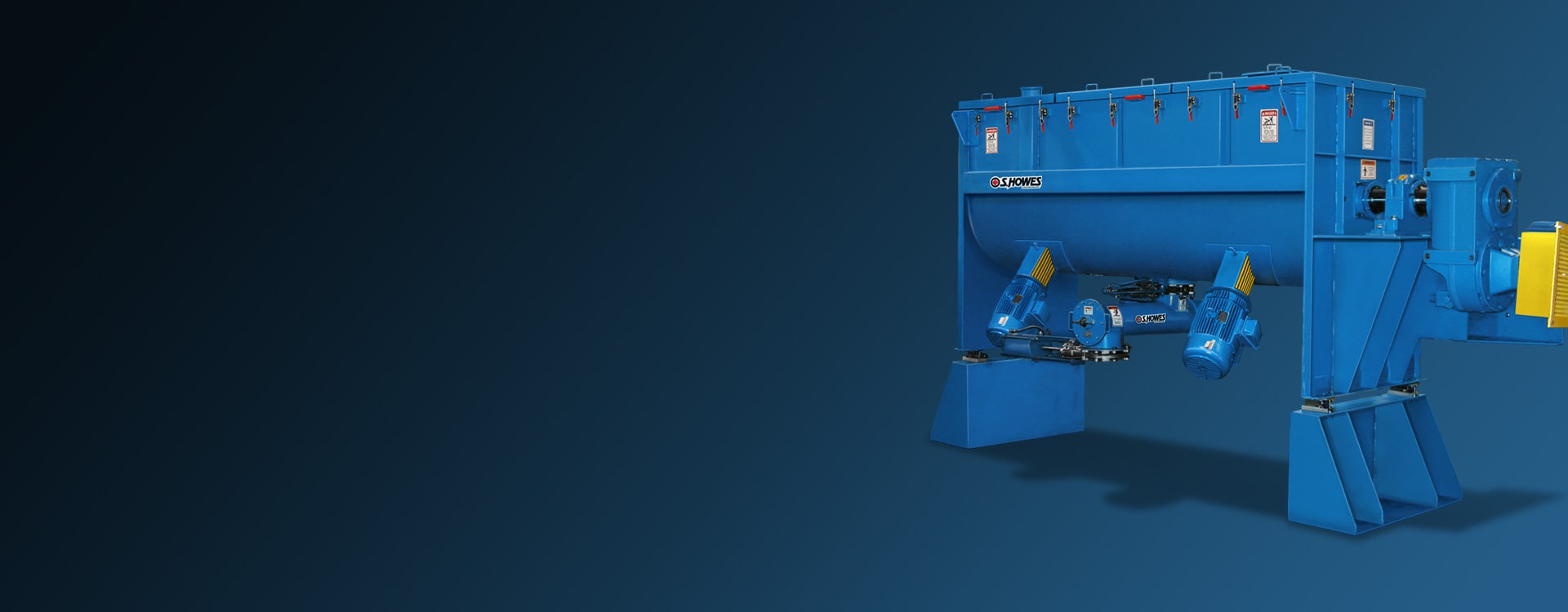

Mixall

Versatile bulk solids mixing with uniform product blends.

Our Mixall mixers and blenders are versatile for almost all industries and are economically designed to process a wide range of products while providing uniform product blends. Its heavy-duty construction provides years of low-maintenance processing. Mixing is accomplished using either the S. Howes original double ribbon or adjustable paddle agitator, and custom assemblies are available. The Mixall provides a low initial “per ton” cost and features a leakproof, dustproof design to completely discharge product.

Standard models are available from 4 to 375 cu. ft. (3/4 full) and custom models are available to handle up to 750+ cu. ft. of product.

Let our engineers design the most versatile mixer for your mixing and blending needs.

Features & Benefits

- End plates are reinforced to provide stiffness and support. Blind-end plate is bolted to the tank, and the drive end is welded – both at a 90-degree angle – no radius.

- Uniquely designed double ribbon type agitator assembly features ribbons welded to cross-arms. Paddle agitators feature paddles that can be either welded or bolted to crossarms.

- A solid steel shaft with flange-type bearings may be used when the torque of the cylinder is under 5,000 inchpounds.

- Drive-end bearings and journals will withstand high starting torque at the maximum recommended horsepower. Bearings are 2-1/2 times the calculated radial load. High-quality, self-aligning type bearings are furnished on all Mixalls.

- Bearings are mounted to allow for alignment of cylinder and have lock screws to secure the bearing locations.

- Support cradles under the tank are available to improve heavier load distribution.

Solid Steel Shaft

A solid steel shaft with flange-type bearings may be used when the torque of the cylinder is under 24,000 inchpounds.

Sample Applications

- Food Ingredients

- Pet Food

- Feed

- Slurries

- Powders & Bulk Solids

- And more

Options & Accessories

- Batch and continuous operation

- Double ribbon, paddle, plough-style and custom agitator designs

- High-velocity intensifiers / choppers

- Variety of access options for inlets, covers and inspection manways

- Temperature sensors, level sensors, limit switches

- Explosion-proof motor design

- Chain or belt drive

- Gates and discharge options

Downloads

Test Lab & Innovation Center

Your Material Product. Our Thermal Processing Equipment.

Make sure your new process equipment delivers your desired final material requirements.

Lab Testing

Leverage the CPEG Innovation Center and expertise in process engineering to test material product prior to the design or purchase of bulk solids and material handling equipment.

Testing With Rental Units

When material testing in the Innovation Center is not feasible, S. Howes provides rental equipment that can be shipped directly to your site for reliable testing of powder and bulk solids materials.