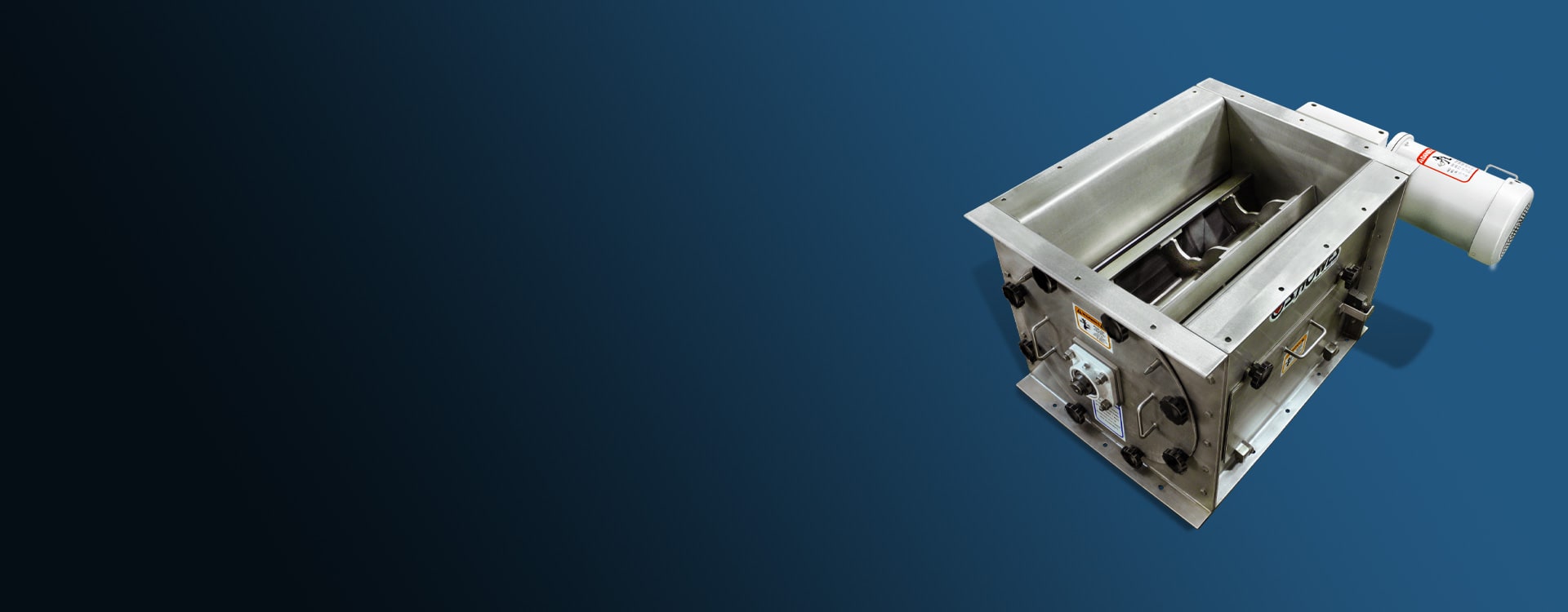

Power Grater

Multifunctional material size reduction machine.

Our Power Grater size reducer features a unique multifunctional design that provides grating, delumping, particle sizing, crushing, shredding, and de-agglomeration of various products. With its low horsepower requirements, low paddle speed, and heavy-duty construction, the S. Howes power grater is an economical choice for reliable size reduction with less fines.

Power Graters can be designed in stainless steel, carbon steel, or other alloys, and screens can be customized to your requirements. The screen cage can be removed with minimal tools for fast screen change and cleaning in sanitary applications. Optional, hinged cleanout doors and view windows allow access to the rotor assembly and all interior casing areas.

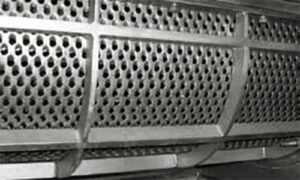

The S. Howes’ Power Grater consists of a dust-tight housing that contains a paddle assembly and an aperture screen. The screen features holes edged by raised cutting edges that grate or shred the product as it is pushed over the screen. The paddles rotate, and the product is rubbed against the grater screen for clean, efficient reduction.

Power through size reduction with the S. Howes Power Grater.

Features & Benefits

- Multifunctional design provides versatility for particle sizing, delumping, crushing, shredding and deagglomeration processes.

- Low paddle rotation speed design for less fines (approximately 88 RPM for single speed models).

- Heavy-duty, rugged construction with few moving parts and dependable long-life components provide extremely low maintenance and high reliability.

- Removable screen cage with minimal tools for fast screen change and cleaning.

- Hinged doors provide quick access to the rotor assembly and interior casing areas.

Sample Applications

- Animal Feed

- Biscuits

- Bread

- Cereal

- Cheese

- Chocolate

- Filter Cake

- Peat Soil

- Peanuts

- Salt

- Bead Blast Media

- Chemicals

- Plastic

- Resin

- Tungsten Powder

Downloads

Options & Accessories

- Resin-lined mild steel casing with stainless steel working parts

- Stainless steel, carbon steel, or special alloy construction

- Single or variable speed drives including mechanical, electrical (AC or DC controllers), and hydraulic

- TEFC, explosion proof or hostile environment motors

- Screen sizes per customer requirements

Test Lab & Innovation Center

Your Material Product. Our Thermal Processing Equipment.

Make sure your new process equipment delivers your desired final material requirements.

Lab Testing

Leverage the CPEG Innovation Center and expertise in process engineering to test material product prior to the design or purchase of bulk solids and material handling equipment.

Testing With Rental Units

When material testing in the Innovation Center is not feasible, S. Howes provides rental equipment that can be shipped directly to your site for reliable testing of powder and bulk solids materials.