Continuous Mixer

Continuous, uniform mixing and blending of liquids and dry solids.

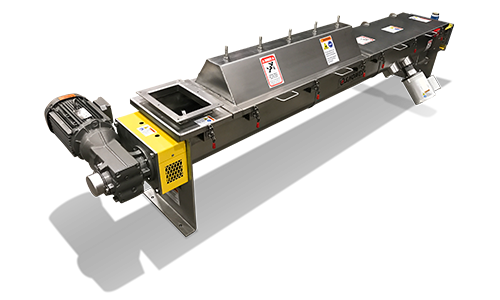

S. Howes Paddle Mixers (Pug Mills) provide continuous, uniform mixing and blending of liquids and dry ingredients. The mixing action of the patented adjustable solid or loop-type paddles on the agitator shaft is gentle and free-flowing /non-plugging, coating products without beating the ingredients to ensure uniform absorption of liquids throughout the mix.

Paddle mixers are available in Simplex (single agitator shaft) and Duplex (twin agitator shaft) models. Capacities range from 1 to 300 tons per hour; custom designs for higher capacities are also available.

S. Howes’ sales and engineering department can recommend a standard design for your application or work with you and your team to develop a custom design, depending on your processing requirements.

Let our engineers build a custom continuous mixer.

General Features & Benefits

- Heavy-duty construction.

- Hanger bearing required over 12 ft.

- Independently adjustable bolted paddles.

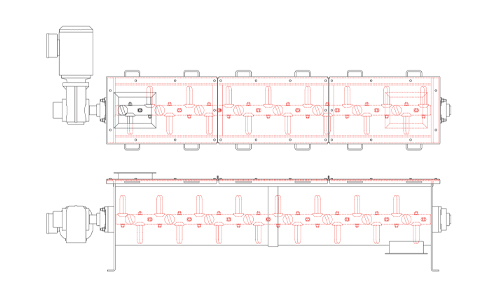

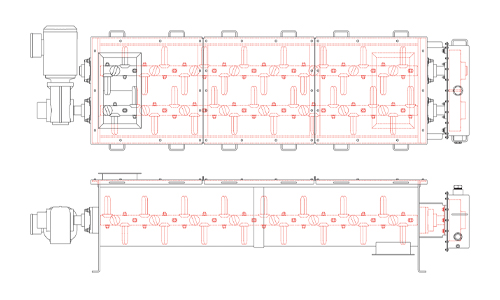

- Single shaft (simplex) and dual shaft (duplex) models.

- Duplex models feature intermeshing paddles with a single drive.

- Direct drive or shaft mounted gear reducer & belt drive.

- Self aligning bearings.

- Carbon steel, stainless steel or other alloys.

Simplex Mixers

Simplex, or single shaft, continuous mixers include 5 standard models ranging from 5 to 12 tons per hour nominal capacity with larger custom models available.

Duplex, or dual shaft, continuous mixers include 10 standard models ranging from 1 to 300 tons per hour nominal capacity with larger custom models available.

Duplex Mixers

Continuous Mixers (Pug Mills)

Suitable for mixing high viscous pastes or free flowing slurries, plastic pellets, cement, pigments, mud, and many more applications. The paddles lift and direct material to produce a gentle but efficient mixing action. Mixing time is variable due to the adjustable paddle design but is typically less than a minute with good coefficient variance and a low degree of particle shear.

Sample Applications

Continuous paddle mixers are ideal for adding liquids to dry materials to make slurries and semi-liquid mixtures and are suitable for processing a wide variety of products including:

- Biosludge

- Animal Feed

- Salt Coating

- Food Products

- Seeds

- Spent Grain

- Gravel & Asphalt

- Crushed Limestone

- Fertilizer

- Lime

- Minerals

- Bentonite

- Corn Feed

- Soybeans

- Rubber & Plastic

- Pellets

- Paper & Wood Products

- Molasses

- Chemicals

- Powders & Slurries

- Frac Sand

- Drill Tailings

- Powdered Detergent

- Fly Ash

Options & Accessories

Paddle Options

- Solid type

- Loop type

- Abrasion-resistant

Liquid Addition

- Spray balls, bars & nozzles

- Drip manifold

- Inlet pipes & valves

Thermal Options

- Heating & Cooling jackets

- Integral or bolt-on

- ASME “U” stamp

Access Ports

- Sanitary clamp fittings

- Inspection doors

- Side access & probe ports

Test Lab & Innovation Center

Your Material Product. Our Thermal Processing Equipment.

Make sure your new process equipment delivers your desired final material requirements.

Lab Testing

Leverage the CPEG Innovation Center and expertise in process engineering to test material product prior to the design or purchase of bulk solids and material handling equipment.

Testing With Rental Units

When material testing in the Innovation Center is not feasible, S. Howes provides rental equipment that can be shipped directly to your site for reliable testing of powder and bulk solids materials.