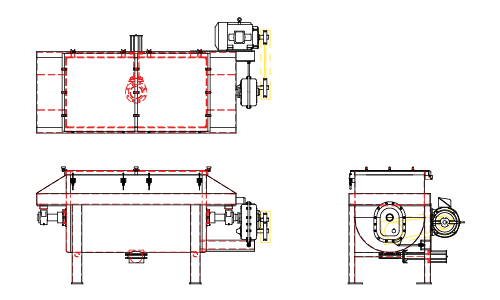

Sanimix Mixers

Sanitary designed mixers used by the world’s leading food, pet food, and pharmaceutical companies.

Our proven sanitary design provides a superior uniform mix complemented by a robust construction. Mixing is accomplished using either a ribbon or paddle agitator. The S. Howes Double-Ribbon Agitator, with the original reverse-spiral design, delivers uniform, high-capacity blending at low power cost. The mix is held in constant suspension, providing an excellent uniform product blend. Paddle assemblies utilize a tumbling motion for mixing and have less product shearing during the process.

Standard sanitary mixing models are available from 4 to 375 cu. ft. (3/4 full) to provide a superior and consistently uniform product blend.

Let our engineers design a mixer for your sanitary application.

Features & Benefits

- Built to food, dairy, or pharmaceutical standards.

- Flanged journals for agitator removal.

- Welded heads with radiused corners.

- High-quality, heavy-duty construction.

- Uniform product blends.

- Complete discharge available.

- Easily to clean.

Mixing For Sanitary Applications

Our sanitary mixers include stainless steel construction where material product is in contact and can be built in USDA and FDA approvable designs.

Construction Details

- All Stainless Steel construction including tank, agitator assembly, and support legs (optional) – ideal for sanitary applications.

- Tank heads include generously formed-radius corners (¾” minimum), eliminating 90 degree angles to provide for easy cleanout.

- Uniquely designed double ribbon type agitator assembly features ribbons welded to cross-arms. Paddle agitators feature paddles that can be either welded or bolted to cross-arms for adjustability.

- Agitator assemblies are constructed with machined flange journals for top removal, thereby reducing cleaning problems typical of traditional bolted tank heads requiring end removal.

- All internal welds are ground smooth and are crack and crevice free. Butt welds are ground flush and corner welds are ground to a radius at least 1/8”. External welds are intermittent with gaps sealed with Devcon (or equivalent).

- Inverted pillow block shaft bearings are hung from a covered shelf to minimize horizontal surfaces where cleaning agents can build up. Build-up of product on bearings is minimized as well.

Sanimix 45

Sanimix 80

Shafting materials are made heavier and can carry up to 60% more horsepower than Sanimix-45 models. Class II Drive is standard for Sanimix-80 models.

Sample Applications

- Pharmaceuticals

- Nutrient Blends

- Spices & Sugar

- Food Powders

- Milk

- Flour

- Infant Formula

- Cereals

- Drink Mixes

- Coffee Creamers

- Cosmetics

- Pet foods

- Specialty Chemicals

- Fermentation

Options & Accessories

- Batch and continuous operation

- Double ribbon, paddle, plough-style and custom agitator designs

- High-velocity intensifiers / choppers

- Variety of access options for inlets, covers and inspection manways

- Temperature sensors, level sensors, limit switches

- Direct, chain, or belt drive

- Gates and discharge options

Downloads

Test Lab & Innovation Center

Your Material Product. Our Thermal Processing Equipment.

Make sure your new process equipment delivers your desired final material requirements.

Lab Testing

Leverage the CPEG Innovation Center and expertise in process engineering to test material product prior to the design or purchase of bulk solids and material handling equipment.

Testing With Rental Units

When material testing in the Innovation Center is not feasible, S. Howes provides rental equipment that can be shipped directly to your site for reliable testing of powder and bulk solids materials.