Filters & Filtration

S. Howes filtration equipment is used for the separation of suspended solids from a liquid stream. This type of equipment is commonly termed “cake filtration” because the build up of solids forms a cake that acts as a filter medium. The filter leaves provide a structure on which the cake can form, as well as a sufficient cross sectional drainage area that enables the filtered liquid to be evacuated as quick as possible. Depending on the characteristics of the solids, the cake can be discharged either as a wet mass or a dry mass, which in turn determines the discharge design of equipment. All units are available in various materials of construction and are constructed and stamped A.S.M.E. code vessels.

Filtration Equipment

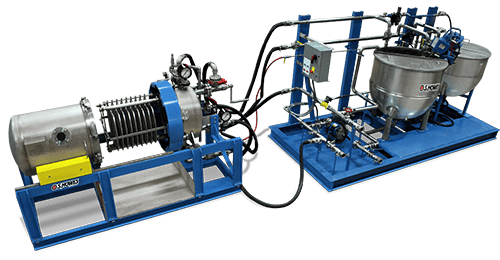

FILTER SYSTEMS

S. Howes designs and builds complete filtration systems, from concept, to start-up & training. Filtration systems are typically skid mounted, factory piped, wired, and programmed to minimize installation time and disruption of production. Filter designs integrate with pre-existing tanks, piping, instrumentation and controls.

Get A Quote

Whether you need a single filter or an entire filtration system, we have you covered.