Skip to content

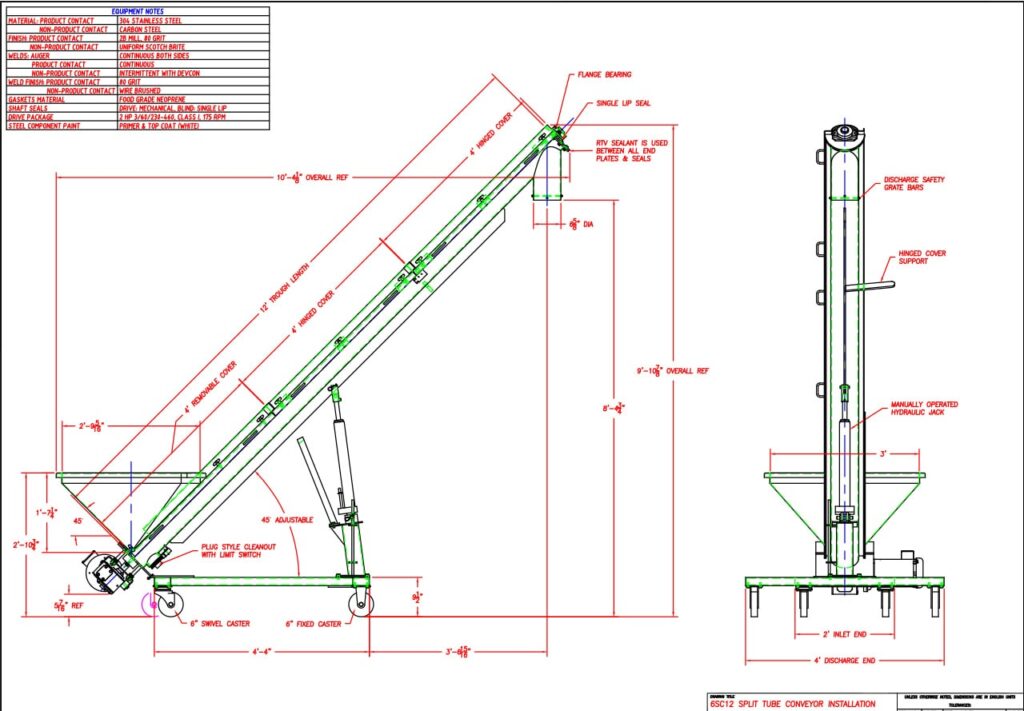

6SC12 Split Tube Conveyors

Standard Design Features

- 6″ diameter screw x 12′ long with 2/3 pitch inlet flighting, balance full pitch flighting

- 2-1/4 ft3 hopper with bolted safety grating

- 6″ standard pipe stub discharge

- 3 HP, 1800 RPM 3/60/230-460V TEFC (4:1) inverter duty motor

- 10:1 gear reducer for final auger speed of approx. 175 RPM

- Standard cleanout with 120 VAC limit switch (mounted not wired)

- Many different hoppers available for the rental units

- Controls, wiring and installation by customer

Construction Details

- 304 Stainless steel construction in product contact areas

- Interior surfaces uniform 80 grit finish

- Exterior surfaces uniform Scotch-Brite finish

- Continuous weld on both sides of flighting

- Welds in contact with product continuous and ground to 80 grit finish

- Welds not in contact with product intermittent and ground smooth, gaps filled with Devcon

- Covers on trough are gasketed, hinged and fastened into place with plastic hand knobs, with 120 VAC limit switch (mounted not wired)

- Mild steel portable base with two (2) rigid and two (2) swivel casters with brakes and hydraulic jack for angle adjustment

- Rotating mechanical shaft seal on the drive and single lip seal on discharge end

- Exterior mild steel components (motor, bearings, etc.) to be one coat primer and one coat white epoxy

To rent a stock item call 716.934.2611 or fill out and submit the form below.