Skip to content

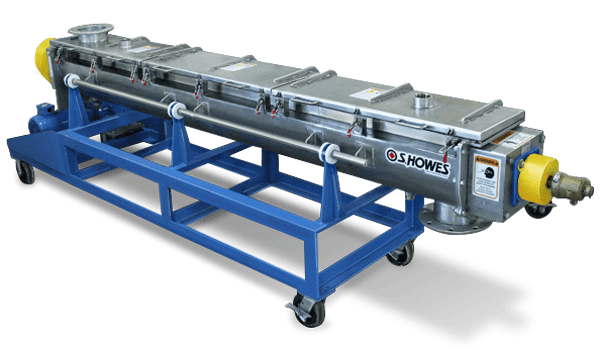

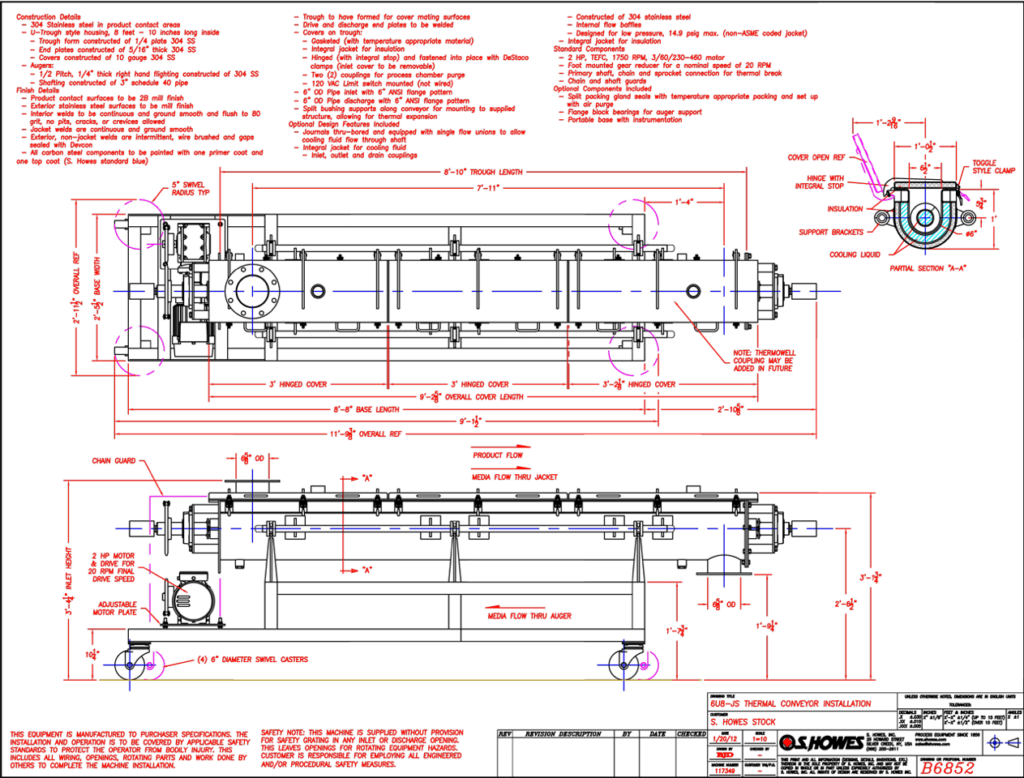

6U8-JS High Temperature Heating / Cooling Conveyor

Standard Design Features

- Integral jacket for insulation, heating and cooling fluid

- Covers on trough are gasketed (with temperature appropriate material)

- Hinged jacket (with integral stop) and fastened into place with quick access clamps

(inlet cover to be removable)

- Journals thru-bored, equipped with single flow unions to allow cooling fluid flow through shaft

- Split packing gland seals with temperature appropriate packing and set up with air purge

- Designed for low pressure, 14.9 psig max. (non-ASME coded jacket)

- 2 HP, TEFC, 1750 RPM, 3/60/230-460 motor

- 120 VAC Limit switch mounted (not wired)

- Split bushing supports along conveyor for mounting to supplied structure allows for thermal expansion

- Foot mounted gear reducer for a nominal speed of 20 RPM

- Portable base with instrumentation

- Internal flow baffles

Construction Details

- Auger features 1/2 Pitch, 1/4″ thick right hand flighting constructed of 304 stainless steel

- 304 stainless steel in product contact areas

- U-Trough style housing, 8′ 10″ long inside

- Product contact surfaces to be 2B mill finish

- Exterior stainless steel surfaces to be mill finish

- Interior welds to be continuous and ground smooth and flush to 80 grit, no pits, cracks, or crevices allowed

- Jacket welds are continuous and ground smooth

- Exterior, non-jacket welds are intermittent, wire brushed and gaps sealed with Devcon

- Trough form constructed of 1/4 plate 304 stainless steel

- End plates constructed of 5/16″ thick 304 stainless steel

- Trough to have formed for cover mating surfaces

- Covers constructed of 10 gauge 304 stainless steel

- Overlapping covers require discharge cover to be opened first

- Saddle supports along conveyor for mounting to supplied structure

- Chain and shaft guards

- Primary shaft, chain and sprocket connection for thermal break

- Drive and discharge end plates to be welded

- 6″ OD plain tube inlet and tube discharge both with 6″ ANSI flange pattern

- Inlet, outlet and drain couplings

- Two (2) couplings for process chamber purge

- Shafting constructed of 3″ schedule 40 pipe

- Heavy-duty shaft pipe with flanged journals

- Flange block bearings for auger support

- All carbon steel components to be painted with one primer coat and one top coat (S. Howes standard blue)

To rent a stock item call 716.934.2611 or fill out and submit the form below.