Skip to content

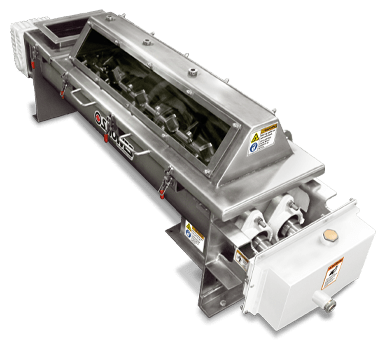

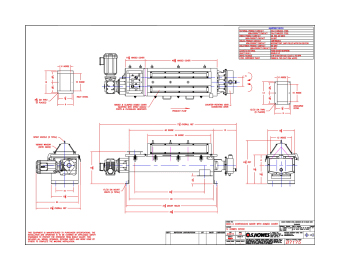

MCD-4 Continuous Duplex Mixer

Standard Design Features

- Solid twin shaft paddle type agitators – one shaft right hand and one shaft left hand

- One shaft extended for drive

- Nominal capacity 1 ton per hour

- Double lip type shaft seals

- Closed cell neoprene gaskets

- Standard flanged bottom outlet discharge

- Counter-rotating gear connecting drive, oil bath lubrication with oil tight enclosed guard

- 3 HP, 1800 RPM, 3/60/230-460 hollow bore gearmotor

- Drive Class I application, complete with shaft mounted gear reducer for a shaft speed of 175 RPM

- Bolted inlet & discharge transitions

- Some units equipped with flat covers

Construction Details

- 46 Fully adjustable and replaceable solid paddles with machined washers to lock paddles to shafts

- Three (3) 2-bolt flange bearings

- 304 Stainless steel construction in product contact areas

- Fully welded tank

- One (1) hinged & clamped domed cover with viewports and spray nozzle ports

- One (1) hinged cover with flanged inlet

- Solid bar shafting finish details

- 7 Gauge tank thickness

- 10 Gauge cover thickness

- All exterior surfaces to be ground to 36 grit finish

- All interior surfaces to be 2B (100-120 grit) finish

- Product contact welds are continuous and ground to finish

- Non-product contact welds are intermittent and gaps filled with food grade Devcon

- All steel components to be painted with one primer coat and one top coat (white)

To rent a stock item call 716.934.2611 or fill out and submit the form below.