Flour Mixing & Bagging System

The Process Challenge

A bakery products manufacturer approached S. Howes to assist in developing and constructing a flour-based mixing and bagging system. This system was to be located in a new facility, allowing the company to expand operations and be closer to the customers of the final packaged product.

The Solution

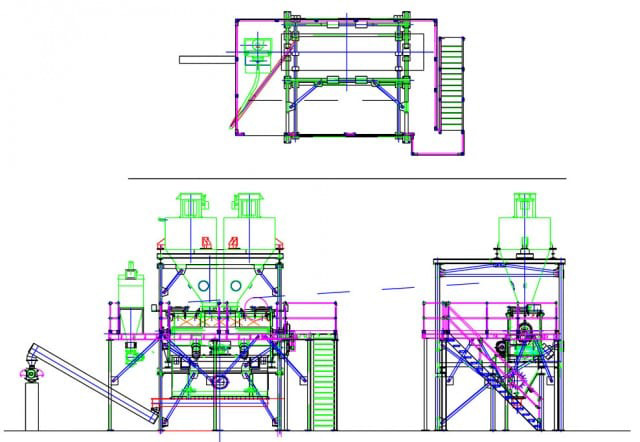

S. Howes designed the system and worked closely with subcontractors who provided several ancillary components. It was designed to handle 5,000 lbs of flour and minor ingredients, which were blended for five minutes per batch. 50 lb. An operator loaded bags on a mezzanine designed to hold three pallets. The product was mixed, sifted, and pneumatically conveyed into a hopper for staging before being loaded into an automatic bagger.

The system was erected at S. Howes’ facility, where the customer inspected and approved the equipment’s quality and functionality.

Components

- M-4212 ES Sanimix Mixer

- Surge Bin

- Framework & Mezzanine Platform

- Bag Dump Station

- 5,000 lb. capacity hopper

- 10” Screw Conveyor

- Power Sifter

- Pneumatic Conveyor

- Lump breaker

- Inclinable Conveyor to Sifter

Photos and drawings are not intended to show or suggest use or non-use of any operator protection systems.

The Result

The system is currently used 24 hours a day, 14 days per two weeks.