Thermal Processing

Thermal processing mixers and conveyors play a crucial role in various industries where precise temperature control is essential for product quality and safety. S. Howes thermal processing machines are designed to heat and cool materials through a continuous or batch processing system while ensuring optimal thermal conditions. Whether it’s production of food products, chemicals, or pharmaceuticals, the line of S. Howes thermal mixers and conveyors achieve precise thermal treatments to meet your requirements.

Lab testing may be required to obtain the best system for achieving the required thermal coefficient of various materials.

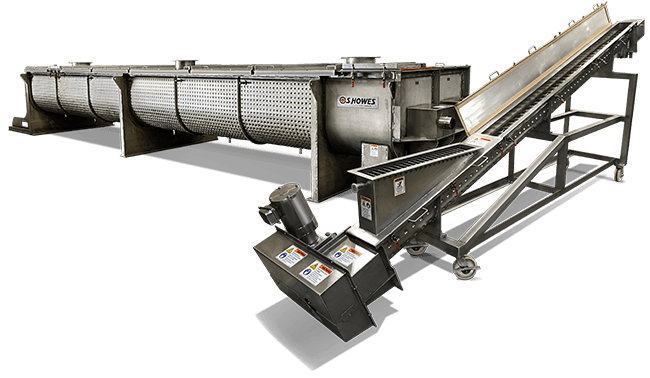

Thermal Processing Equipment

THERMAL PROCESSING SYSTEMS

In the realm of thermal processing mixers, advanced technologies like jacketed mixing vessels and heat exchangers enable precise temperature regulation during mixing operations. This ensures that ingredients are uniformly heated or cooled, contributing to the consistent quality of the final product.

Our thermal conveyors with multiple independent jacket panels are designed to transport materials seamlessly through different stages of the thermal treatment, while maintaining the desired temperature throughout the process line.

Get A Quote

Whether you need to heat or cool your product while mixing or conveying, contact S. Howes for your next thermal processing solution.