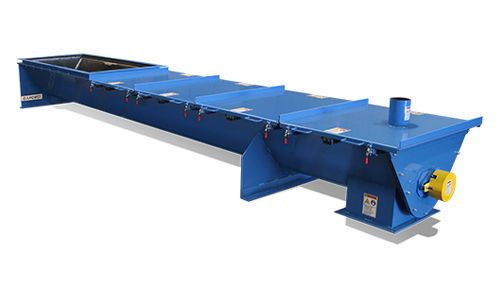

Industrial Screw Conveyor Systems

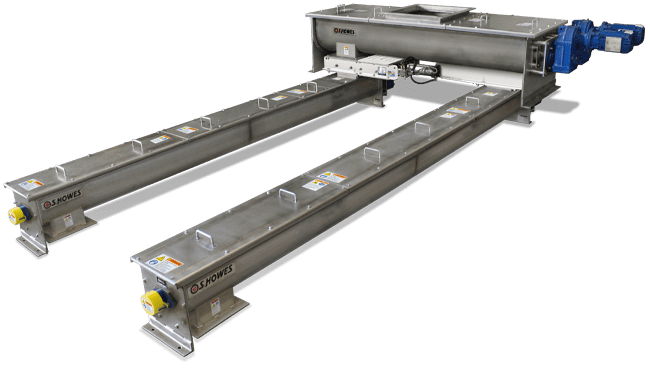

Conveying systems are custom engineered by S. Howes to meet difficult process requirements. Our custom conveying systems offer a range of benefits across various industries. Whether it’s automating food processes such as unloading systems with sanitary screw conveyors and feeders with a quick cleanout design, incorporating thermal jackets into conveying systems to cool high-temperature chemicals or designing portable or inclinable split-tube conveyors that provide adaptability, S. Howes has you covered.

Our conveying equipment includes heavy-duty and sanitary screw auger designs, mechanical split tube conveyors, tubular conveyors, and U-trough conveyors with dewatering, heating, cooling, mixing, and drying options. Feeders can be customized with several shaft seals and various hopper designs.

Mechanical Screw Conveyors

CONVEYING SYSTEMS

When multistep processes require innovative solutions, our mechanical conveying experts work to understand your unique challenges and build a blueprint for success.

Get A Quote

Materials and process steps can be validated in our lab to facilitate the delivery of an efficient, reliable solution that streamlines processes and boosts productivity.