Industrial Mixers

Our reputation for building quality, robust, and proven processing equipment manifests itself in our comprehensive line of mixers and blenders. Regardless of the powder and bulk solids industry, S. Howes designs and builds quality into every mixer.

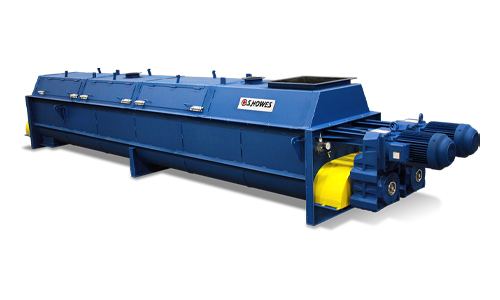

Mixers are available in a variety of features and configurations including ribbon, paddle, and custom agitators, continuous and batch operation, single and double shaft mixing action, heavy-duty capacities, sanitary designs, and jacketed units for thermal processing.

Mixers for Processing Powders & Bulk Solids

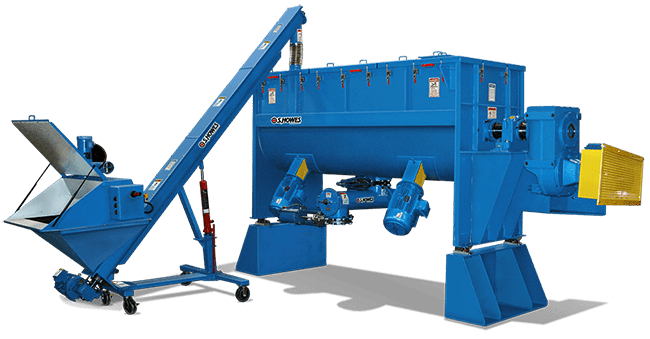

MIXING SYSTEMS

When mixing and other processes such as screening, size reduction, or transferring material downstream is necessary, our engineers will design a complete integrated system. And if simulation under various mixing conditions is required, our engineered-to-order lab mixers provide accurate, scale-up simulation prior to specifying or building production machines.

Laboratory testing in our Innovation Center may be required prior to designing and manufacturing mixers. Our testing equipment will be used to validate process and product requirements and the data will be used to build mixers and mixing systems.

Get A Quote

Whether you need a single piece of process equipment or an entire process line, we have you covered. Contact the industrial mixing professionals at S. Howes.