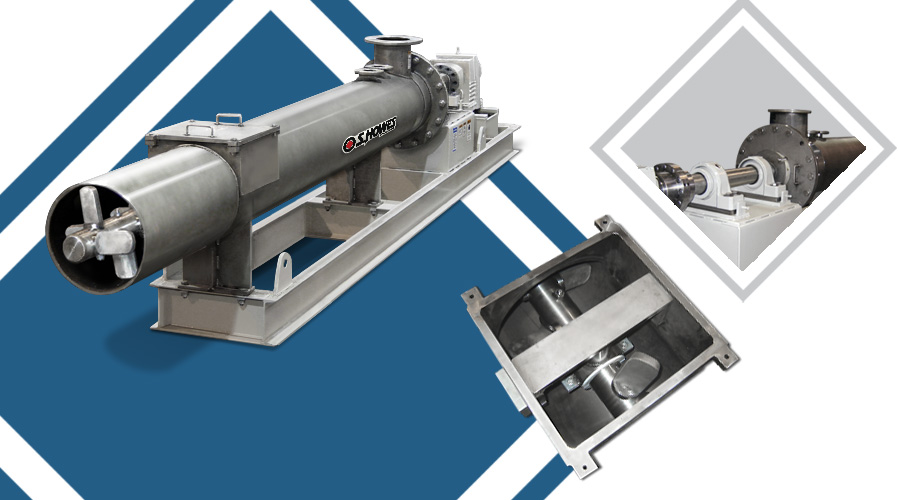

Continuous Mixer & Reactor

The Process Challenge

A major international chemical manufacturer needed to replace an existing reactor with one that could double capacity and reduce maintenance. The process continuously blended a dry granular material with a hot strong acid solution and discharged it horizontally into a kiln. The chemical reaction allowed the evolution of an acid gas that could not mix with air.

The Solution

S. Howes proposed a specially modified version of the C-121 continuous mixer with standard, independently adjustable, replaceable paddles along with several adaptations:

- Alloy-20 construction to stand up to the high temperature acid

- Replaced the traditional U-style body with a Tubular body to eliminate covers

- Eliminated discharge end bearing to allow direct discharge into the kiln

- Supported shaft with twin drive-end bearings and custom hanger bearing

- Custom mechanical shaft seal using engineered resins selected for compatibility

- Incorporated spay nozzles to provide highly efficient distribution of the acid

The Result

S. Howes successfully achieved the goals of the customer:

- The desired increase in production rate was achieved using the combination of the spray nozzles with the superior mixing performance of the S. Howes traditional and time-proven design

- The customer can now replace individual paddles with basic tools instead of continually swapping entire repaired agitator assemblies

- The mixer actually had a slightly smaller footprint and required no increase in power to achieve the desired results