Food Ingredient Unloading & Conveying System

The Process Challenge

A food manufacturer was expanding its operations and contacted S. Howes to design a conveying system to automate and increase the volume of spices that it was able to process.

The Solution

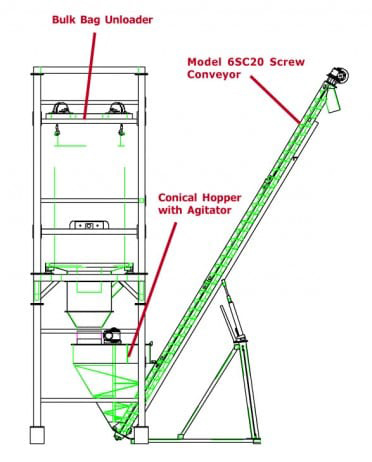

S. Howes’ solution started with a bulk bag unloader which dispensed material into a conical hopper which fed the product into a 20 foot screw conveyor before the product entered a bagging system. The spice mix was salty and dense making it very difficult to convey. An agitator in the hopper was necessary to ensure a smooth and consistent feed into the screw conveyor.

Components

- Flexible Bulk Bag Unloading Station

- Support Framework

- 22 cu. ft. Capacity Hopper

- Hopper Agitator

- 6″ Diameter Screw Conveyor

- Consolidated Control Panel

Photos and drawings are not intended to show or suggest use or non-use of any operator protection systems.

The Result

The S. Howes’ system enabled the company to increase production and resulted in a more consistent and efficient transfer of food ingredients.