Pancake Mixing System

The Process Challenge

S. Howes, Inc. was approached by a food processor to design a system to automate the mixing and bagging of pancake mix which had been previously labor intensive. Operations were constrained by 11-foot high ceilings.

The Solution

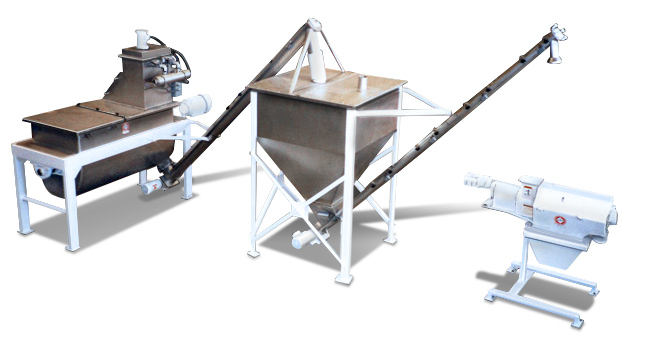

S. Howes, Inc. designed and constructed an enclosed, sanitary system which included a bag-dump station directly connected to a sanitary double ribbon mixer where ingredients were mixed and transferred to a split-tube conveyor and surge hopper before the product passed through a custom-designed conveyor into a bagging station.

Components

- Bag Dump Station mounted on the blender

- S-366 Double Ribbon Blender

- 6′ Split tube Screw Conveyor

- Surge Hopper

- 4′ Tubular Screw Conveyor with cleanout access doors

The Result

The closed system was fully automated, reduced labor costs, improved product consistency and was built to accommodate all height constraints as well as sanitary specifications. This system was able to mix and bag 3,600 lbs. of pancake mix per hour.