Rental Equipment

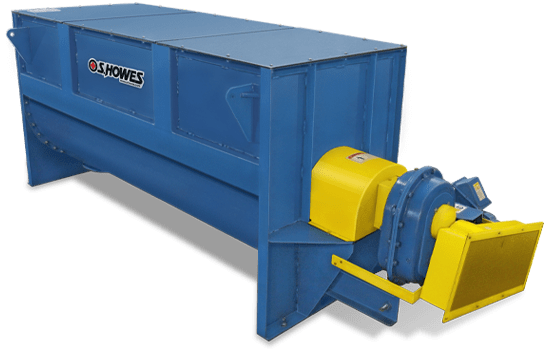

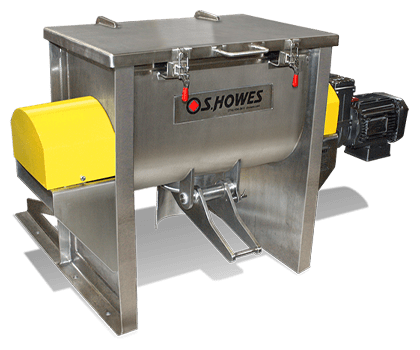

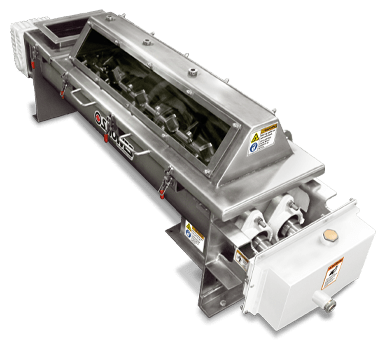

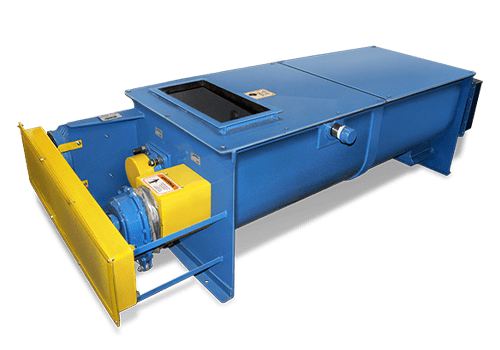

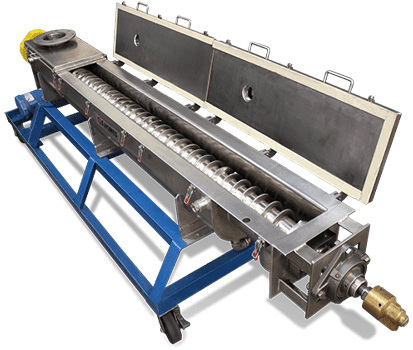

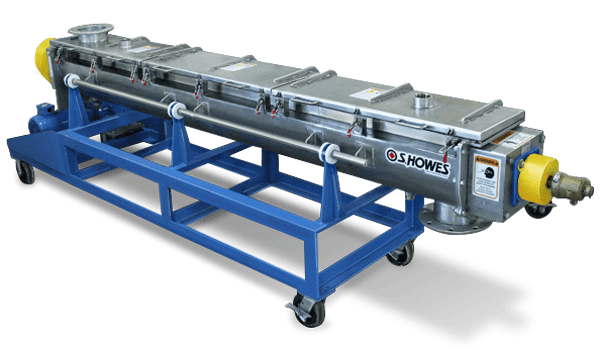

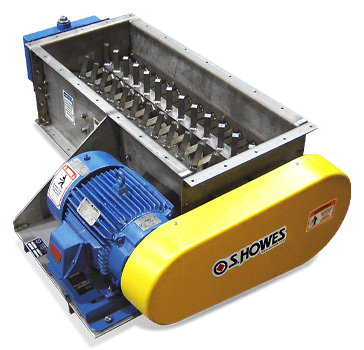

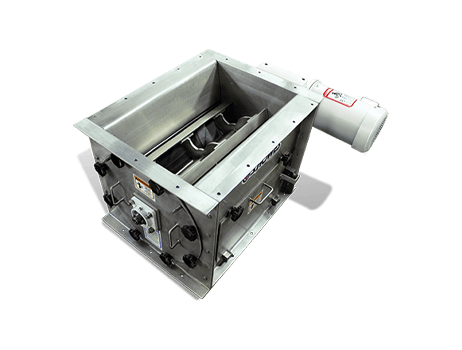

Our commitment to designing and manufacturing the best process equipment year after year is as strong as ever. The same quality workmanship extends into the complete line of S. Howes rental equipment. Our rental machines are built to last, from mixers, screeners, and size reduction equipment to conveyors, feeders, and filtration equipment.

With our design experience and extensive industry knowledge, you won’t find a better partner for your rental process equipment needs. Whether you need to rent equipment for a single job or want to test our equipment before you buy, we have you covered. Our experienced technicians will provide technical specifications for every rental machine.

Delivered & Installed At Your Facility

Inquire About Our Rental Equipment

Rent Processing Equipment

Browse our currently available models for industrial processing equipment rentals below. The available equipment changes regularly, so please contact us to ensure we have that particular unit in stock. We’ll respond to your inquiry as soon as possible to discuss your needs.