Posted on February 15th, 2024 by showes

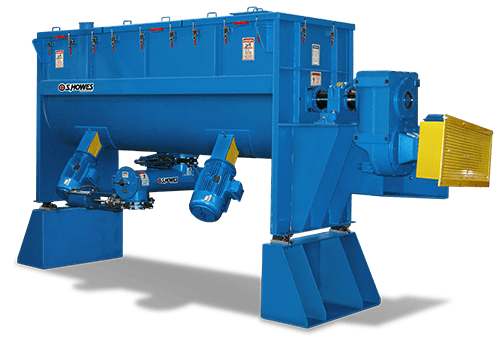

At S. Howes, our expertise lies in designing equipment and processing machinery for your specific requirements. We recently worked on a project with a forest products company. Their challenge? Building a system capable of transforming excess wood from sawmills into something valuable: animal bedding.

In this blog, we’ll share how our CPEG lab played a vital role in that process. You’ll see how we designed and tested a solution to turn waste into a functional product.

From Concept to Reality – Designing and Testing the System

As material testing and consulting experts, our team considered this project a challenge. We designed a system that efficiently moved the wood from the sawmill to the knife cutter. Further ahead, the chips were sent to a Snappy Shaker, responsible for the right size and shape of the product for animal bedding.

But in this process, there was one challenge that our team faced: different types of wood, varying in size and moisture. This meant we had to be smart with the design that we engineered.

In our CPEG material testing lab, we thoroughly tested each part of the system. Our primary goal was to ensure it was safe and functioned well. Our tests allowed us to improve around many areas, and in the end, we got the final system capable of handling a staggering 4,000 pounds of woodchips per hour!

Practical Application and Expertise in Material Testing

At S. Howes, our CPEG Test Lab is central to our work. We focus on creating custom-made equipment and processing machinery. During the design phase, material testing is important. Our lab rigorously tests to ensure each system meets its unique requirements. This approach is essential for projects like turning sawmill wood into animal bedding.

Sometimes, lab testing doesn’t suffice the need. We shift the equipment to your facility for testing in such exceptional cases.

With over 160 years of extensive experience, we possess expertise across diverse industries. In addition to manufacturing high-quality equipment, we excel in providing comprehensive support for its operation and maintenance. Moreover, our dedicated team is ever prepared to offer expert guidance and tailored solutions to address your business requirements unique challenges effectively.

How S. Howes Turned Wood Waste Into Value

Our work with the forest products company reflects our skills and capabilities in material testing and consulting to tackle significant challenges in building engineer-to-order products.

Turning excess wood into animal bedding wasn’t easy, but our CPEG lab made it possible. Projects like these prove how important it is to have a lab where we can engineer custom processing machinery for your specific needs.

Get in touch with us to learn more about how our expertise and experience can help you design equipment and processing machinery for your specific applications and facility. We’re always here to help and would love to work on your next big idea!