Posted on December 19th, 2023 by showes

If your business specializes in manufacturing pet food or similar dry products, the choice of mixers you utilize holds significant importance. Among various options available, horizontal batch mixers stand out for a few compelling reasons.

This article delves into the key considerations when choosing a horizontal batch mixer and other types of mixers.

Types of Mixers

- Batch Mixers: Utilized for mixing a wide variety of products, including bulk powders, cement materials, liquid additions, and food powders, these style mixers blend all ingredients until a uniform material is achieved, which is then ejected in a single batch. They have a long, U-trough-shaped shell with a horizontal agitator shaft inside. There are multiple agitator options, but the main two styles of agitators are ribbon agitators and paddle agitators.

- Ribbon Mixers: This agitator style helps blend bulk powders such as flour and chemical powder easily. The spiral ribbon agitator imparts a high shear force into the materials, producing a great mixing action. These versatile mixers offer quick, homogeneous blending in the food and pharmaceutical industries.

- Paddle Mixers: This agitator style can also blend bulk powders but is often used with filter cake, sticky, or paste-like products that can wrap around the ribbon agitator. The paddle agitator produces a mixing action that lifts and pushes material, providing a gentle mixing action.

- Continuous Mixers: Operating on the principle of two counter-rotating, high-speed, non-intermeshing rotors in a long mixing chamber, these mixers provide high-intensity mixing, providing a continuous flow of mixed materials from the charging port to the discharge port.

- Vertical Mixers: Vertical mixers are very common for operations in smaller farms. In these, you put the ingredients to mix at the bottom. Vertical augers – spiral blades – carry them up to the mixer’s upper part. The mix then falls to the floor level and is picked and carried up by the augers.

With this, let’s now look at the key considerations to bear in mind when selecting a mixer suitable for your operations.

Key Considerations to Choose a Horizontal Batch Mixer

Here are some simple but essential things to keep in mind when you are choosing a horizontal batch mixer:

What It’s Made Of: The Basics Matter

Always look for a mixer of top-notch steel that will last long. Ask the supplier where they get their steel and what it’s made of. If you need stainless steel, get the supporting documentation proving its quality.

The Shaft

Cheap mixer manufacturers use small solid shafts. These solid shafts sound nice but can fracture easily. Quality mixers use larger hollow shafts to spread the force around the entire shaft. They also run the agitator posts through the shaft instead of simply welding the post to the shaft. These features greatly reduce the risk of breaking a post or shaft during production.

How It’s Welded

Welding holds your mixer together. Good welds last long. MIG welds are usually good. Ask the supplier how they test their welds. This is vital for the mixer’s long-term use.

High-quality and Reliable Parts

The mixer will have other parts like motors and bearings. Make sure the company partners with known brands for these. It’s a sign of overall quality.

Maintenance

You’ll need to replace parts like valves and gaskets as you use the mixer. Make sure the supplier can send you these parts quickly. A good supplier will also have a smart and reliable maintenance plan.

After Sales Support

Buying the mixer isn’t the end of the road. You’ll need help operating the unit and maybe even later. Make sure the supplier will stick around to help and offer quality aftermarket support.

Remember, it’s not just a one-time buy. You’re putting money into your business. Pay attention to these points, and you’ll pick a mixer that does the job and lasts long.

Summing Up

For quality mixes, going with the right mixer is essential. While considering the list, you will find different mixers, such as batch, continuous, and vertical. Although, for dry bulk solid mixing, horizontal batch mixers should be a good option to consider. Before you go ahead and buy one, do ask these questions:

- How good is the material?

- What’s the shaft like?

- Are the welds strong?

- Are components such as motors and bearings of high quality?

- Is there a good plan for preventive maintenance?

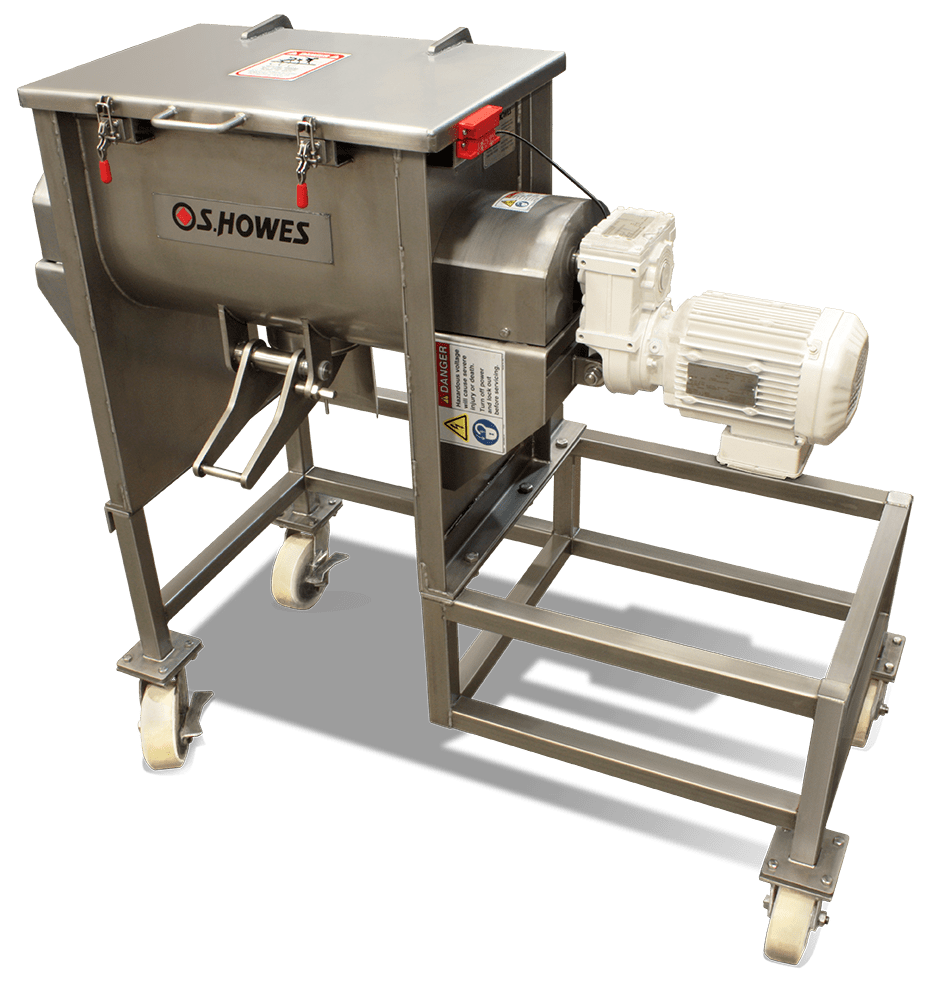

Why Choose S. Howes

When finding reliable, high-quality horizontal batch mixers, look no further. At S. Howes, we have an established reputation for manufacturing dependable mixers that deliver efficient results for your operations.

Whether you require a top-grade mixer that aligns with your work needs or one that complies with industry guidelines, S. Howes is your ultimate solution. Invest in a mixer that will consistently perform year after year.

Feel free to reach out to us; we will be more than happy to address any inquiries you may have!