Posted on March 20th, 2024 by showes

In the dynamic realm of industrial processing, efficient material handling is not just a necessity—it’s an art form. A crucial cog in this complex machinery is the screw conveyor. Renowned for its efficiency, reliability, and adaptability, it emerges as an essential component in numerous sectors.

The real power of these workhorses is their versatility—they are not simply one-size-fits-all equipment. With the ability to be customized to unique requirements, they seamlessly blend into various processes across industries. But what makes them tick? And how do they contribute to enhancing operational efficiency?

The Mechanics of Screw Conveyors

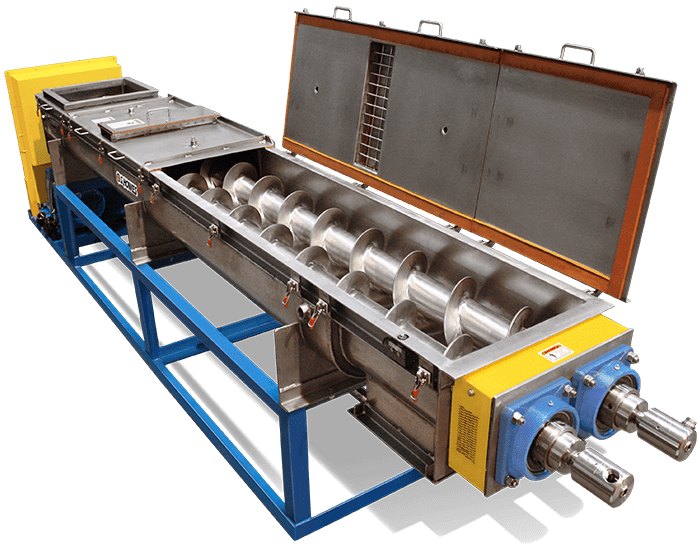

At its core, a screw conveyor is an ingeniously simple piece of equipment. It comprises a rotating helical screw blade (also known as an auger) housed within a tube or trough. As the screw rotates, it moves the material along from one end to the other. This simple yet effective design enables precise control over the flow rate, making it an invaluable tool in many industrial processes.

But why stop merely moving materials from point A to point B? Screw conveyors can also be used in thermal heating and cooling processes. These conveyors can heat or cool materials while being transferred, effectively accomplishing two processes in one machine.

The Power of Customization

At S. Howes, we understand that no two processes are identical. Different industries have different needs, and different materials behave in various ways. That’s why we offer custom screw conveyors tailored to meet your specific production needs. We can incorporate specialized features into your custom screw conveyor design, such as:

- Specialized hopper configurations

- Custom-engineered hopper agitators

- Control Panels with Variable frequency drives (VFDs)

- Portable designs

- Split-Tube inclined screws

- Heating and cooling options

- Live-bottom bins

- Multiple augers in a single housing

Our engineering team can design conveyors for unique applications requiring special materials like Inconel, Hastelloy, Duplex 2205. We can also design conveyors for applications in the food industry with high internal polishes and clean-in-place (CIP) features.

A Testament to Reliability and Longevity

Our commitment to quality and longevity is evident in our products. Some of our oldest pieces of equipment today are over 75 years old and still in operation. With over 175,000 machines built, we have gained the trust of our customers—80% of whom are repeat buyers.

We leverage modern manufacturing techniques to ensure that our screw conveyors not only meet but surpass industry standards. Our stringent quality control processes ensure that every screw conveyor we manufacture is worthy of carrying the S. Howes name.

Testing and Rental Units: Try Before You Buy

Unsure about how well a screw conveyor would work for your specific application? S.Howes has a test lab available for pilot and lab-scale testing to assess the feasibility of conveying specific products. We even offer rental units for on-site testing before you make the final investment.

Whether you need a reliable solution for material handling or a customized piece of equipment for unique industrial applications, S. Howes’ screw conveyors have you covered. Combining efficiency with reliability while offering unprecedented customization options—our screw conveyors truly embody the spirit of industrial innovation. With S.Howes, you’re not just buying a machine but investing in a legacy of quality and reliability over 160 years and counting. Contact us for more information.